How does precision pneumatic components processing achieve micron-level precision control?

Release Time : 2025-02-14

In the field of modern industrial manufacturing, precision pneumatic components are widely used in automation control systems, pneumatic tools and various mechanical equipment due to their high precision, high performance and high reliability. In order to ensure that these components can meet the stringent application requirements, it is essential to achieve micron-level precision control during the processing.

The precision pneumatic components processing process is a complex and sophisticated system engineering. To achieve micron-level precision control, it is necessary to start from multiple links such as material selection, processing equipment, manufacturing process and quality control.

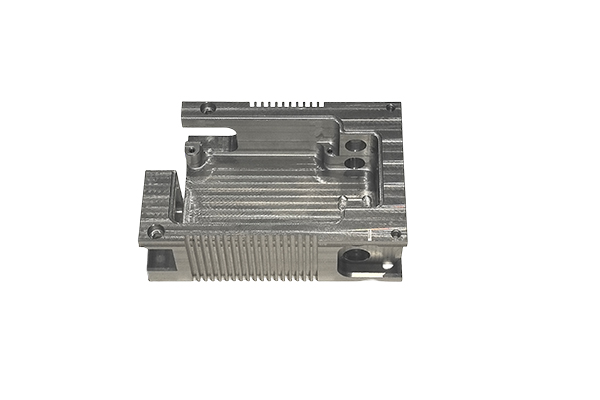

In terms of material selection, precision pneumatic components usually use high-strength, high-wear-resistant and corrosion-resistant high-quality alloy materials. These materials not only have excellent physical and chemical properties, but also can maintain stable shape and size during the processing process, providing a solid foundation for achieving high-precision processing.

In terms of processing equipment, precision pneumatic components processing relies on advanced CNC machine tools and precision measuring instruments. CNC machine tools have the characteristics of high precision, high stability and high degree of automation, which can ensure that every step in the processing process meets the micron-level precision requirements. At the same time, precision measuring instruments such as laser interferometers and three-coordinate measuring machines can conduct comprehensive and accurate inspections on processed components to ensure that product performance meets design requirements.

In terms of manufacturing technology, the processing of precision pneumatic components covers multiple links such as casting, forging, machining, and heat treatment. Each link requires strict control of process parameters and operating specifications to ensure the accuracy and performance of the product. Especially in the machining link, the use of high-precision turning, milling, drilling and other processes, combined with advanced tool and fixture technology, can achieve precise control of component shape and size.

Quality control is a key link to ensure the high performance of precision pneumatic components. From the storage of raw materials to the delivery of finished products, each link requires strict quality inspection and monitoring. By establishing a sound quality management system and adopting advanced quality inspection methods, quality problems in the production process can be discovered and solved in a timely manner to ensure product consistency and reliability.

In summary, it takes many efforts and cooperation to achieve micron-level precision control in the processing of precision pneumatic components. Only in this way can the high performance and high reliability of the product be ensured to meet the stringent requirements of modern industrial manufacturing for precision pneumatic components.

The precision pneumatic components processing process is a complex and sophisticated system engineering. To achieve micron-level precision control, it is necessary to start from multiple links such as material selection, processing equipment, manufacturing process and quality control.

In terms of material selection, precision pneumatic components usually use high-strength, high-wear-resistant and corrosion-resistant high-quality alloy materials. These materials not only have excellent physical and chemical properties, but also can maintain stable shape and size during the processing process, providing a solid foundation for achieving high-precision processing.

In terms of processing equipment, precision pneumatic components processing relies on advanced CNC machine tools and precision measuring instruments. CNC machine tools have the characteristics of high precision, high stability and high degree of automation, which can ensure that every step in the processing process meets the micron-level precision requirements. At the same time, precision measuring instruments such as laser interferometers and three-coordinate measuring machines can conduct comprehensive and accurate inspections on processed components to ensure that product performance meets design requirements.

In terms of manufacturing technology, the processing of precision pneumatic components covers multiple links such as casting, forging, machining, and heat treatment. Each link requires strict control of process parameters and operating specifications to ensure the accuracy and performance of the product. Especially in the machining link, the use of high-precision turning, milling, drilling and other processes, combined with advanced tool and fixture technology, can achieve precise control of component shape and size.

Quality control is a key link to ensure the high performance of precision pneumatic components. From the storage of raw materials to the delivery of finished products, each link requires strict quality inspection and monitoring. By establishing a sound quality management system and adopting advanced quality inspection methods, quality problems in the production process can be discovered and solved in a timely manner to ensure product consistency and reliability.

In summary, it takes many efforts and cooperation to achieve micron-level precision control in the processing of precision pneumatic components. Only in this way can the high performance and high reliability of the product be ensured to meet the stringent requirements of modern industrial manufacturing for precision pneumatic components.