How to ensure the corrosion resistance and sealing of materials in solenoid valve processing?

Release Time : 2025-01-30

As a key component in pneumatic components, the stability and reliability of the performance of solenoid valves largely depend on the corrosion resistance and sealing of materials. In the processing of solenoid valves, it is crucial to ensure these two points, which are directly related to the service life and working efficiency of solenoid valves.

Solenoid valves often need to work in various harsh environments, such as high temperature, high pressure, humidity or corrosive media. Therefore, when processing solenoid valves, choosing corrosion-resistant materials is a crucial first step. Stainless steel is one of the commonly used materials in solenoid valve processing. Its excellent corrosion resistance can resist the erosion of various chemical substances and is suitable for harsh environments such as petroleum, chemical industry, and seawater treatment. In addition, some special non-metallic materials, such as polytetrachloroethylene and natural rubber, are also widely used in the sealing parts of solenoid valves due to their good corrosion resistance.

In addition to the selection of materials, the processing technology of solenoid valves also has an important influence on corrosion resistance and sealing. During the processing, the processing temperature, time and environment of the materials need to be strictly controlled to avoid unnecessary chemical or physical changes in the materials, thereby affecting their corrosion resistance. At the same time, for the processing of sealing parts, it is necessary to ensure its surface finish and precision to achieve the best sealing effect.

In the assembly process of solenoid valves, the inspection of sealing is also an indispensable part. Usually, pressure testing and other methods are used to test the sealing performance of solenoid valves to ensure that there will be no leakage problems during use. In addition, for some special application scenarios, such as high pressure, high temperature or highly corrosive media, the solenoid valves need to be subjected to additional anti-corrosion treatment, such as spraying anti-corrosion coatings, thermal spraying, etc., to further enhance their corrosion resistance and sealing.

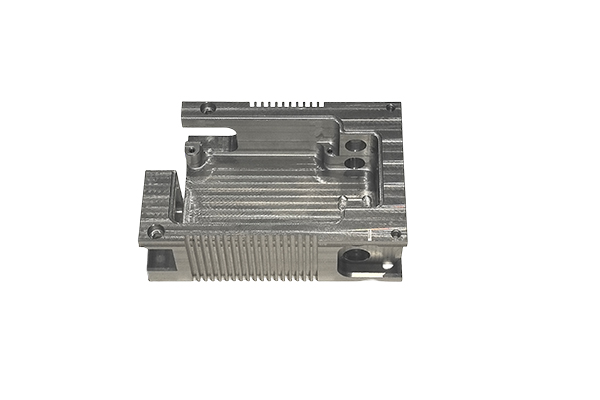

With the advancement of science and technology, the processing technology of solenoid valves is also constantly innovating. For example, the use of advanced CNC processing equipment and detection technology can greatly improve the processing accuracy and sealing performance of solenoid valves. At the same time, some new materials and surface treatment technologies also provide new solutions for the corrosion resistance and sealing of solenoid valves.

In summary, ensuring the corrosion resistance and sealing of materials in solenoid valve processing is a complex and meticulous process, which requires comprehensive consideration from multiple aspects such as material selection, processing technology, and assembly inspection. Only in this way can the solenoid valve be ensured to work stably and reliably in various harsh environments.

Solenoid valves often need to work in various harsh environments, such as high temperature, high pressure, humidity or corrosive media. Therefore, when processing solenoid valves, choosing corrosion-resistant materials is a crucial first step. Stainless steel is one of the commonly used materials in solenoid valve processing. Its excellent corrosion resistance can resist the erosion of various chemical substances and is suitable for harsh environments such as petroleum, chemical industry, and seawater treatment. In addition, some special non-metallic materials, such as polytetrachloroethylene and natural rubber, are also widely used in the sealing parts of solenoid valves due to their good corrosion resistance.

In addition to the selection of materials, the processing technology of solenoid valves also has an important influence on corrosion resistance and sealing. During the processing, the processing temperature, time and environment of the materials need to be strictly controlled to avoid unnecessary chemical or physical changes in the materials, thereby affecting their corrosion resistance. At the same time, for the processing of sealing parts, it is necessary to ensure its surface finish and precision to achieve the best sealing effect.

In the assembly process of solenoid valves, the inspection of sealing is also an indispensable part. Usually, pressure testing and other methods are used to test the sealing performance of solenoid valves to ensure that there will be no leakage problems during use. In addition, for some special application scenarios, such as high pressure, high temperature or highly corrosive media, the solenoid valves need to be subjected to additional anti-corrosion treatment, such as spraying anti-corrosion coatings, thermal spraying, etc., to further enhance their corrosion resistance and sealing.

With the advancement of science and technology, the processing technology of solenoid valves is also constantly innovating. For example, the use of advanced CNC processing equipment and detection technology can greatly improve the processing accuracy and sealing performance of solenoid valves. At the same time, some new materials and surface treatment technologies also provide new solutions for the corrosion resistance and sealing of solenoid valves.

In summary, ensuring the corrosion resistance and sealing of materials in solenoid valve processing is a complex and meticulous process, which requires comprehensive consideration from multiple aspects such as material selection, processing technology, and assembly inspection. Only in this way can the solenoid valve be ensured to work stably and reliably in various harsh environments.