How to achieve waterproof and dustproof functions for consumer electronic products during shell processing?

Release Time : 2025-01-02

In the shell processing process of consumer electronic products, it is crucial to achieve waterproof and dustproof functions, which is not only related to the durability and reliability of the product, but also directly affects the user experience. To achieve this goal, manufacturers use a variety of technologies and methods in the shell processing process.

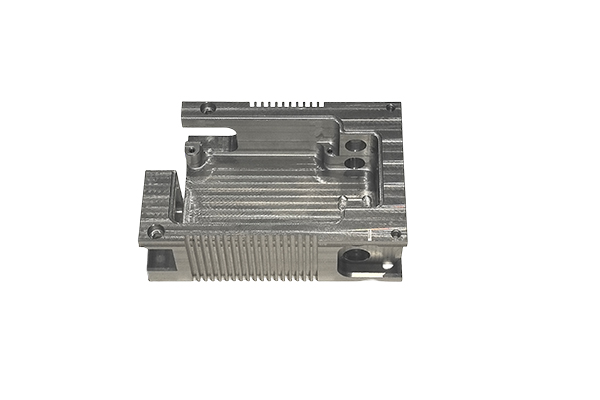

First of all, the choice of materials is the basis. For consumer electronic products that need to be waterproof and dustproof, the shell material is usually selected from polymer materials with excellent sealing performance and corrosion resistance, such as specific plastics or alloys. These materials are easy to form during the processing process and can effectively block the intrusion of moisture and dust.

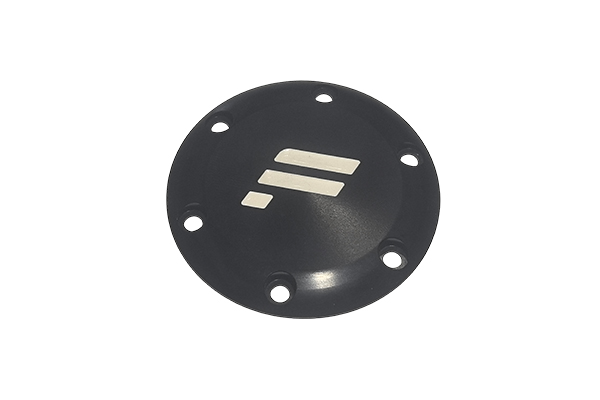

Secondly, structural design is also critical. During shell processing, designers will carefully plan the internal structure of the product to ensure that all openings and gaps are properly closed. For example, by adding design elements such as sealing gaskets, waterproof coatings or dustproof grids, the waterproof and dustproof performance of the shell can be enhanced. These design elements are precisely embedded or coated in key parts during the processing process, effectively preventing the penetration of moisture and dust.

In addition, the processing technology also plays a vital role. During the shell processing process, manufacturers will use advanced molding, cutting and assembly technologies to ensure the accuracy and integrity of the shell. These processes not only improve the manufacturing quality of the product, but also provide a solid foundation for waterproof and dustproof design.

Finally, quality control is an indispensable link. After the shell processing is completed, the manufacturer will conduct rigorous waterproof and dustproof tests on the product to ensure that its performance meets the established standards and requirements. These tests usually include immersion tests, spray tests, and pressure tests to comprehensively evaluate the waterproof and dustproof capabilities of the shell.

In summary, achieving the waterproof and dustproof function of consumer electronic products during the shell processing process requires comprehensive consideration of material selection, structural design, processing technology, and quality control. By adopting advanced technologies and methods, manufacturers can provide users with more durable and reliable consumer electronic products.

First of all, the choice of materials is the basis. For consumer electronic products that need to be waterproof and dustproof, the shell material is usually selected from polymer materials with excellent sealing performance and corrosion resistance, such as specific plastics or alloys. These materials are easy to form during the processing process and can effectively block the intrusion of moisture and dust.

Secondly, structural design is also critical. During shell processing, designers will carefully plan the internal structure of the product to ensure that all openings and gaps are properly closed. For example, by adding design elements such as sealing gaskets, waterproof coatings or dustproof grids, the waterproof and dustproof performance of the shell can be enhanced. These design elements are precisely embedded or coated in key parts during the processing process, effectively preventing the penetration of moisture and dust.

In addition, the processing technology also plays a vital role. During the shell processing process, manufacturers will use advanced molding, cutting and assembly technologies to ensure the accuracy and integrity of the shell. These processes not only improve the manufacturing quality of the product, but also provide a solid foundation for waterproof and dustproof design.

Finally, quality control is an indispensable link. After the shell processing is completed, the manufacturer will conduct rigorous waterproof and dustproof tests on the product to ensure that its performance meets the established standards and requirements. These tests usually include immersion tests, spray tests, and pressure tests to comprehensively evaluate the waterproof and dustproof capabilities of the shell.

In summary, achieving the waterproof and dustproof function of consumer electronic products during the shell processing process requires comprehensive consideration of material selection, structural design, processing technology, and quality control. By adopting advanced technologies and methods, manufacturers can provide users with more durable and reliable consumer electronic products.