How to improve the response speed of precision pneumatic components processing in high-speed pneumatic applications?

Release Time : 2024-12-11

In high-speed pneumatic applications, improving the response speed of precision pneumatic components processing is a key technical challenge. Improving the response speed can not only improve the overall performance of the system, but also achieve more precise control in automation, robotics, aerospace and other fields.

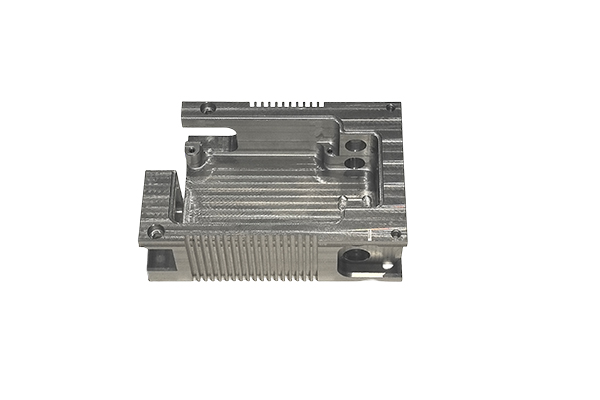

1. Optimize the design of pneumatic components

Reduce the volume and weight of components: By optimizing the design and reducing the volume and weight of pneumatic components, the flow path and inertia of the gas can be reduced, thereby improving the response speed.

Use lightweight materials: Using lightweight materials (such as aluminum alloys, composite materials, etc.) to manufacture pneumatic components can reduce the inertia of the components and improve the response speed.

Streamlined design: Designing streamlined pneumatic components can reduce the resistance to gas flow and reduce the lag time of the gas.

2. Improve the pneumatic circuit

Shorten the length of the pneumatic circuit: By shortening the length of the pneumatic circuit, the transmission time of the gas in the circuit can be reduced, thereby improving the response speed.

Reduce elbows and joints in pneumatic circuits: Reducing the number of elbows and joints in pneumatic circuits can reduce the flow resistance of gas and improve the response speed.

Use quick connectors: Using quick connectors can reduce the connection time in the pneumatic circuit and improve the response speed of the system.

3. Increase the supply pressure and stability of the gas source

Increase the supply pressure: Increasing the supply pressure of the gas source can increase the flow speed of the gas, thereby improving the response speed of the pneumatic components.

Maintain the stability of the gas source: Stable gas source pressure can reduce the fluctuation of pneumatic components when starting and stopping, and improve the response speed of the system.

4. Use high-speed solenoid valves

Select high-speed solenoid valves: High-speed solenoid valves have faster switching speeds and can complete switching actions within milliseconds, thereby improving the response speed of the pneumatic system.

Optimize the control signal of the solenoid valve: By optimizing the control signal of the solenoid valve, the switching delay of the solenoid valve is reduced, and the response speed is further improved.

5. Use advanced control technology

Use digital control technology: Using digital control technology (such as PID control, fuzzy control, etc.) can more accurately control the action of pneumatic components and reduce response time.

Introducing feedback control: By introducing feedback control, the status of pneumatic components can be monitored in real time, and adjustments can be made according to the feedback signal, which can improve the response speed of the system.

6. Optimizing the sealing performance of pneumatic components

Improving sealing performance: Optimizing the sealing performance of pneumatic components and reducing gas leakage can improve the response speed of the pneumatic system.

Using high-performance sealing materials: Using high-performance sealing materials (such as fluororubber, polytetrafluoroethylene, etc.) can reduce the friction and wear of seals and improve the response speed.

7. Reduce the friction and inertia of pneumatic components

Reducing friction: By lubricating or using low-friction materials to reduce the friction inside the pneumatic components, the movement speed of the components can be increased.

Reducing inertia: By optimizing the design and reducing the inertia of pneumatic components, the start and stop speed of the components can be increased, thereby improving the response speed.

8. Using parallel pneumatic circuits

Parallel pneumatic circuits: By connecting multiple pneumatic circuits in parallel, the flow channel of the gas can be increased, the residence time of the gas in the circuit can be reduced, and the response speed of the system can be improved.

9. Use pre-compressed gas technology

Pre-compressed gas technology: Using pre-compressed gas technology in pneumatic systems can quickly release high-pressure gas when needed and improve the response speed of the system.

10. Optimize the installation and commissioning of pneumatic components

Reasonable installation of pneumatic components: Reasonable installation of pneumatic components ensures the shortest movement path and reduces unnecessary movement time.

Accurately debug the pneumatic system: By accurately debugging the pneumatic system, ensure the coordinated work of each component and reduce the response time.

By optimizing the design of pneumatic components, improving the pneumatic circuit, increasing the supply pressure and stability of the gas source, using high-speed solenoid valves, using advanced control technology, optimizing sealing performance, reducing friction and inertia, using parallel pneumatic circuits, using pre-compressed gas technology, and optimizing installation and commissioning, the response speed of precision pneumatic components processing in high-speed pneumatic applications can be effectively improved. The comprehensive application of these methods can significantly improve the overall performance of the pneumatic system and meet the needs of high-speed pneumatic applications.

1. Optimize the design of pneumatic components

Reduce the volume and weight of components: By optimizing the design and reducing the volume and weight of pneumatic components, the flow path and inertia of the gas can be reduced, thereby improving the response speed.

Use lightweight materials: Using lightweight materials (such as aluminum alloys, composite materials, etc.) to manufacture pneumatic components can reduce the inertia of the components and improve the response speed.

Streamlined design: Designing streamlined pneumatic components can reduce the resistance to gas flow and reduce the lag time of the gas.

2. Improve the pneumatic circuit

Shorten the length of the pneumatic circuit: By shortening the length of the pneumatic circuit, the transmission time of the gas in the circuit can be reduced, thereby improving the response speed.

Reduce elbows and joints in pneumatic circuits: Reducing the number of elbows and joints in pneumatic circuits can reduce the flow resistance of gas and improve the response speed.

Use quick connectors: Using quick connectors can reduce the connection time in the pneumatic circuit and improve the response speed of the system.

3. Increase the supply pressure and stability of the gas source

Increase the supply pressure: Increasing the supply pressure of the gas source can increase the flow speed of the gas, thereby improving the response speed of the pneumatic components.

Maintain the stability of the gas source: Stable gas source pressure can reduce the fluctuation of pneumatic components when starting and stopping, and improve the response speed of the system.

4. Use high-speed solenoid valves

Select high-speed solenoid valves: High-speed solenoid valves have faster switching speeds and can complete switching actions within milliseconds, thereby improving the response speed of the pneumatic system.

Optimize the control signal of the solenoid valve: By optimizing the control signal of the solenoid valve, the switching delay of the solenoid valve is reduced, and the response speed is further improved.

5. Use advanced control technology

Use digital control technology: Using digital control technology (such as PID control, fuzzy control, etc.) can more accurately control the action of pneumatic components and reduce response time.

Introducing feedback control: By introducing feedback control, the status of pneumatic components can be monitored in real time, and adjustments can be made according to the feedback signal, which can improve the response speed of the system.

6. Optimizing the sealing performance of pneumatic components

Improving sealing performance: Optimizing the sealing performance of pneumatic components and reducing gas leakage can improve the response speed of the pneumatic system.

Using high-performance sealing materials: Using high-performance sealing materials (such as fluororubber, polytetrafluoroethylene, etc.) can reduce the friction and wear of seals and improve the response speed.

7. Reduce the friction and inertia of pneumatic components

Reducing friction: By lubricating or using low-friction materials to reduce the friction inside the pneumatic components, the movement speed of the components can be increased.

Reducing inertia: By optimizing the design and reducing the inertia of pneumatic components, the start and stop speed of the components can be increased, thereby improving the response speed.

8. Using parallel pneumatic circuits

Parallel pneumatic circuits: By connecting multiple pneumatic circuits in parallel, the flow channel of the gas can be increased, the residence time of the gas in the circuit can be reduced, and the response speed of the system can be improved.

9. Use pre-compressed gas technology

Pre-compressed gas technology: Using pre-compressed gas technology in pneumatic systems can quickly release high-pressure gas when needed and improve the response speed of the system.

10. Optimize the installation and commissioning of pneumatic components

Reasonable installation of pneumatic components: Reasonable installation of pneumatic components ensures the shortest movement path and reduces unnecessary movement time.

Accurately debug the pneumatic system: By accurately debugging the pneumatic system, ensure the coordinated work of each component and reduce the response time.

By optimizing the design of pneumatic components, improving the pneumatic circuit, increasing the supply pressure and stability of the gas source, using high-speed solenoid valves, using advanced control technology, optimizing sealing performance, reducing friction and inertia, using parallel pneumatic circuits, using pre-compressed gas technology, and optimizing installation and commissioning, the response speed of precision pneumatic components processing in high-speed pneumatic applications can be effectively improved. The comprehensive application of these methods can significantly improve the overall performance of the pneumatic system and meet the needs of high-speed pneumatic applications.