How does Shell Processing meet the requirements of different design styles?

Release Time : 2024-11-27

At a time when the consumer electronics market is booming, product Shell Processing is like an artistic sculpture, which needs to cleverly match various design styles from simple and modern to retro and gorgeous to highlight the unique charm of the product.

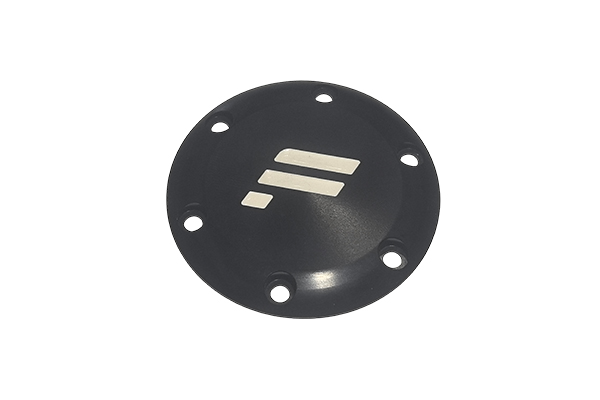

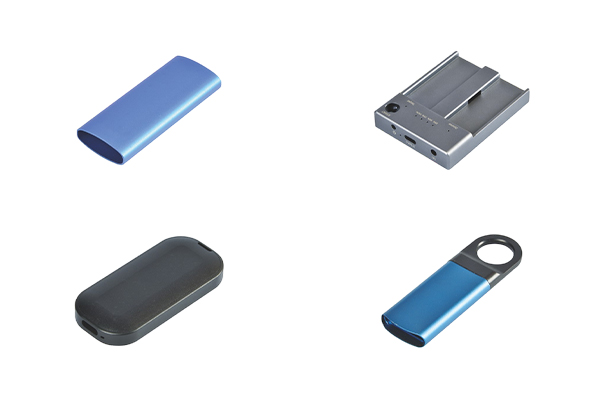

The simple style pursues the ultimate purity, and Shell Processing focuses on neat lines and smooth surfaces. In the injection molding process, the mold accuracy is strictly controlled to ensure the uniform thickness of the shell wall and achieve a smooth appearance. Like most smart bracelet shells, the high-gloss injection molding process gives the surface a delicate and smooth texture, reflecting the beauty of simplicity, without redundant decoration, only the true color and smooth touch of the material, interpreting the tonality of efficient and refined life. The metal shell is often subjected to fine brushing treatment, polished in a specific direction, and a regular and fine texture is pulled out, which is both non-slip and adds low-key luxury, which fits the positioning of business and simple electronic products, such as the A-side design of a thin notebook, which is capable when opened and closed.

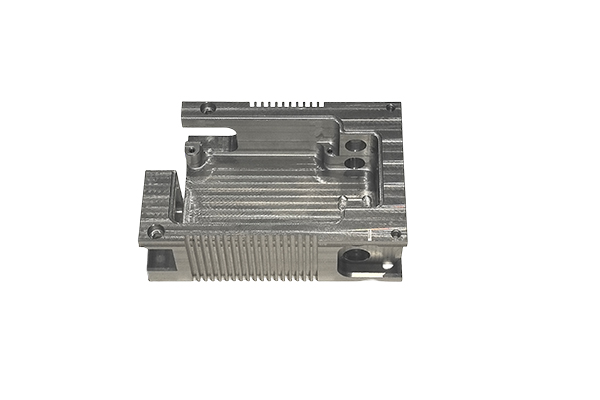

The technological style is fond of complex geometry and novel material combinations. 3D printing technology is very useful. It is built layer by layer according to the design model, and accurately shapes polyhedrons, hollow and other fantasy structures to meet the needs of science fiction shapes. Some concept earphone shells use this process to achieve irregular shapes that seem to come from the future interstellar, and are matched with transparent or translucent materials to reveal the internal precision circuit components and show the core of science and technology. For the metal part, CNC machining (CNC) uses high-precision milling and drilling to carve details, with sharp edges and hard lines, showing mechanical aesthetics, which meets the "cyber" appearance demands of smart wearables and high-end e-sports equipment.

Retro style design digs deep into the rich mine of traditional craftsmanship. The plastic shell imitates the wood texture. The basic shape is first injection molded, and then the realistic wood grain is covered on the surface by heat transfer or water transfer. With the old paint treatment, it simulates the traces of time and is suitable for the Bluetooth speaker shell in the shape of a retro radio. The metal shell adopts antique electroplating to create a mottled bronze and old silver effect, with rounded corners and classical carved frames, showing elegance and heaviness, awakening the memory of the old times, making retro-style electronic products a carrier of cultural emotions and showing a different style.

Shell Processing relies on multiple processes to tailor the design style, carve the appearance, give the product a soul, and stand out in the market competition with its "appearance".

The simple style pursues the ultimate purity, and Shell Processing focuses on neat lines and smooth surfaces. In the injection molding process, the mold accuracy is strictly controlled to ensure the uniform thickness of the shell wall and achieve a smooth appearance. Like most smart bracelet shells, the high-gloss injection molding process gives the surface a delicate and smooth texture, reflecting the beauty of simplicity, without redundant decoration, only the true color and smooth touch of the material, interpreting the tonality of efficient and refined life. The metal shell is often subjected to fine brushing treatment, polished in a specific direction, and a regular and fine texture is pulled out, which is both non-slip and adds low-key luxury, which fits the positioning of business and simple electronic products, such as the A-side design of a thin notebook, which is capable when opened and closed.

The technological style is fond of complex geometry and novel material combinations. 3D printing technology is very useful. It is built layer by layer according to the design model, and accurately shapes polyhedrons, hollow and other fantasy structures to meet the needs of science fiction shapes. Some concept earphone shells use this process to achieve irregular shapes that seem to come from the future interstellar, and are matched with transparent or translucent materials to reveal the internal precision circuit components and show the core of science and technology. For the metal part, CNC machining (CNC) uses high-precision milling and drilling to carve details, with sharp edges and hard lines, showing mechanical aesthetics, which meets the "cyber" appearance demands of smart wearables and high-end e-sports equipment.

Retro style design digs deep into the rich mine of traditional craftsmanship. The plastic shell imitates the wood texture. The basic shape is first injection molded, and then the realistic wood grain is covered on the surface by heat transfer or water transfer. With the old paint treatment, it simulates the traces of time and is suitable for the Bluetooth speaker shell in the shape of a retro radio. The metal shell adopts antique electroplating to create a mottled bronze and old silver effect, with rounded corners and classical carved frames, showing elegance and heaviness, awakening the memory of the old times, making retro-style electronic products a carrier of cultural emotions and showing a different style.

Shell Processing relies on multiple processes to tailor the design style, carve the appearance, give the product a soul, and stand out in the market competition with its "appearance".