Solenoid valve processing environmentally friendly materials create a new benchmark for stability and longevity

Release Time : 2025-04-23

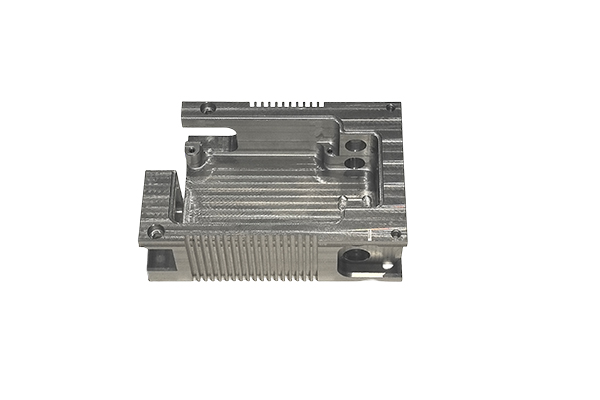

In the field of industrial automation and precision control, solenoid valves and precision pneumatic components are undoubtedly core components. They are like the heart of precision machinery, driving the smooth operation of the entire system. With the continuous advancement of technology and the improvement of environmental awareness, how to create a solenoid valve processing that is both efficient, stable, environmentally friendly and durable has become a focus of common concern within and outside the industry. Today, we will discuss a new processing solution for solenoid valves and precision pneumatic components that combines environmentally friendly materials, strong stability, stable pressure detection and long service life.

The application of environmentally friendly materials is the primary highlight of this innovative solution. Traditional materials are often accompanied by resource consumption and environmental pollution during production and use. The new solenoid valve processing parts use recyclable, low-energy environmentally friendly materials, which not only reduces carbon emissions during the production stage, but also reduces the impact on the environment during use. The choice of this material is not only the practice of the concept of green manufacturing, but also a commitment to future sustainable development.

Strong stability is another major advantage of these solenoid valve processing components. In industrial environments, solenoid valve processing and pneumatic components need to face various complex working conditions, such as high temperature, high pressure, vibration, etc. In order to ensure that the components can still work stably under these extreme conditions, advanced manufacturing processes and strict quality control systems are used in the processing process. From material selection to precision processing, every link has been carefully designed and optimized to ensure that the components can maintain the stability of pressure detection at various temperatures, providing solid guarantee for the precise control of the system.

Another significant feature of this innovative solution is that the service life is more than 5 years. Traditional components often need to be replaced in a short time due to wear and aging, which increases maintenance costs and downtime. The new solenoid valves and pneumatic components have significantly extended their service life by optimizing material structure, improving manufacturing accuracy, and enhancing wear and corrosion resistance. This not only reduces the long-term operating costs of users, but also improves the overall reliability of the system.

In summary, the solenoid valve processing solenoid valve and precision pneumatic component processing solution, which combines environmentally friendly materials, strong stability, stable pressure detection and long service life, has undoubtedly brought new breakthroughs in the field of industrial automation and precision control. It not only meets the market demand for efficient, stable and environmentally friendly products, but also injects new vitality into the sustainable development of the industry. In the future, with the continuous advancement of technology and the continuous expansion of applications, we have reason to believe that this innovative solution will play an important role in more fields and promote industrial manufacturing to develop in a greener, more efficient and intelligent direction.

The application of environmentally friendly materials is the primary highlight of this innovative solution. Traditional materials are often accompanied by resource consumption and environmental pollution during production and use. The new solenoid valve processing parts use recyclable, low-energy environmentally friendly materials, which not only reduces carbon emissions during the production stage, but also reduces the impact on the environment during use. The choice of this material is not only the practice of the concept of green manufacturing, but also a commitment to future sustainable development.

Strong stability is another major advantage of these solenoid valve processing components. In industrial environments, solenoid valve processing and pneumatic components need to face various complex working conditions, such as high temperature, high pressure, vibration, etc. In order to ensure that the components can still work stably under these extreme conditions, advanced manufacturing processes and strict quality control systems are used in the processing process. From material selection to precision processing, every link has been carefully designed and optimized to ensure that the components can maintain the stability of pressure detection at various temperatures, providing solid guarantee for the precise control of the system.

Another significant feature of this innovative solution is that the service life is more than 5 years. Traditional components often need to be replaced in a short time due to wear and aging, which increases maintenance costs and downtime. The new solenoid valves and pneumatic components have significantly extended their service life by optimizing material structure, improving manufacturing accuracy, and enhancing wear and corrosion resistance. This not only reduces the long-term operating costs of users, but also improves the overall reliability of the system.

In summary, the solenoid valve processing solenoid valve and precision pneumatic component processing solution, which combines environmentally friendly materials, strong stability, stable pressure detection and long service life, has undoubtedly brought new breakthroughs in the field of industrial automation and precision control. It not only meets the market demand for efficient, stable and environmentally friendly products, but also injects new vitality into the sustainable development of the industry. In the future, with the continuous advancement of technology and the continuous expansion of applications, we have reason to believe that this innovative solution will play an important role in more fields and promote industrial manufacturing to develop in a greener, more efficient and intelligent direction.