Explore the precise grasp of CNC precision metal hardware mechanical fixture custom processing and assembly

Release Time : 2025-04-09

In modern manufacturing, the demand for high-precision processing is growing. In order to meet this demand, CNC machine tool (CNC) technology has been continuously developed, and one of the key components, CNC precision metal hardware mechanical fixture custom processing and assembly, has become an important factor in ensuring processing quality and efficiency.

1. What is CNC precision metal hardware mechanical fixture custom processing and assembly?

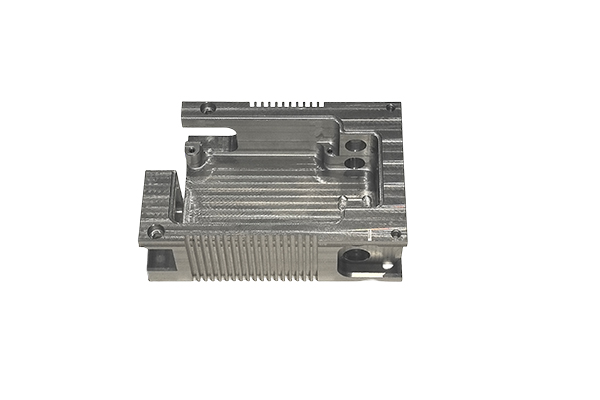

CNC precision metal hardware mechanical fixture custom processing and assembly is a tool specially designed to fix workpieces for precise processing operations. Its main function is to ensure the stability of the position of the workpiece during processing, thereby improving processing accuracy and efficiency. This type of fixture is usually made of high-quality metal materials, with high strength, wear resistance and good dimensional stability, and can maintain excellent performance in various harsh working environments.

2. Key elements of precise grasp

High-precision design: Excellent CNC precision metal hardware mechanical fixture custom processing and assembly first needs to have a high-precision design concept. This includes the optimized design of the fixture structure to ensure that errors are minimized and can adapt to workpieces of different shapes and sizes.

Advanced material selection: The use of advanced materials is essential to improve the performance of the fixture. For example, the use of high-strength alloy steel or titanium alloy can increase the durability of the fixture while reducing deformation problems caused by long-term use.

Flexible adjustment mechanism: In order to adapt to a variety of processing requirements, some high-end fixtures are equipped with adjustable components, allowing users to quickly adjust the clamping force and positioning accuracy according to specific tasks, greatly improving production flexibility.

Intelligent integration: With the promotion of the concept of Industry 4.0, more and more intelligent technologies are being incorporated into CNC precision metal hardware mechanical fixture custom processing and assembly. For example, sensors monitor the clamping state and automatically adjust parameters to ensure optimal processing conditions.

Looking to the future, with the development of intelligent manufacturing technology, CNC precision metal hardware mechanical fixture custom processing and assembly will also usher in new changes. On the one hand, paying more attention to environmental protection and energy saving will become a new trend in the development of the industry; on the other hand, artificial intelligence and big data analysis technology will further promote the development of fixtures in the direction of intelligence, making the processing process more automated and efficient.

As a bridge between machine tools and workpieces, CNC precision metal hardware mechanical fixture custom processing and assembly plays a vital role in achieving efficient and high-quality production. Through the exploration and practice of the above aspects, we can better understand and master how to use these tools to achieve higher processing accuracy and contribute to the continuous progress of the manufacturing industry.

1. What is CNC precision metal hardware mechanical fixture custom processing and assembly?

CNC precision metal hardware mechanical fixture custom processing and assembly is a tool specially designed to fix workpieces for precise processing operations. Its main function is to ensure the stability of the position of the workpiece during processing, thereby improving processing accuracy and efficiency. This type of fixture is usually made of high-quality metal materials, with high strength, wear resistance and good dimensional stability, and can maintain excellent performance in various harsh working environments.

2. Key elements of precise grasp

High-precision design: Excellent CNC precision metal hardware mechanical fixture custom processing and assembly first needs to have a high-precision design concept. This includes the optimized design of the fixture structure to ensure that errors are minimized and can adapt to workpieces of different shapes and sizes.

Advanced material selection: The use of advanced materials is essential to improve the performance of the fixture. For example, the use of high-strength alloy steel or titanium alloy can increase the durability of the fixture while reducing deformation problems caused by long-term use.

Flexible adjustment mechanism: In order to adapt to a variety of processing requirements, some high-end fixtures are equipped with adjustable components, allowing users to quickly adjust the clamping force and positioning accuracy according to specific tasks, greatly improving production flexibility.

Intelligent integration: With the promotion of the concept of Industry 4.0, more and more intelligent technologies are being incorporated into CNC precision metal hardware mechanical fixture custom processing and assembly. For example, sensors monitor the clamping state and automatically adjust parameters to ensure optimal processing conditions.

Looking to the future, with the development of intelligent manufacturing technology, CNC precision metal hardware mechanical fixture custom processing and assembly will also usher in new changes. On the one hand, paying more attention to environmental protection and energy saving will become a new trend in the development of the industry; on the other hand, artificial intelligence and big data analysis technology will further promote the development of fixtures in the direction of intelligence, making the processing process more automated and efficient.

As a bridge between machine tools and workpieces, CNC precision metal hardware mechanical fixture custom processing and assembly plays a vital role in achieving efficient and high-quality production. Through the exploration and practice of the above aspects, we can better understand and master how to use these tools to achieve higher processing accuracy and contribute to the continuous progress of the manufacturing industry.