What are the key points of quality control in copper nut injection nut embedded parts processing?

Release Time : 2025-03-20

The key points of quality control in copper nut injection nut embedded parts processing are the key links to ensure product performance, reliability and safety.

In copper nut injection nut embedded parts processing, the quality of raw materials is directly related to the performance of the final product. Therefore, high-quality copper materials and injection molding materials that meet the standards should be selected. Copper materials should have good electrical conductivity, thermal conductivity and corrosion resistance, while injection molding materials should have good fluidity and strength. Before the raw materials are put into storage, they must be strictly inspected, including appearance inspection, chemical composition analysis, mechanical properties testing, etc., to ensure that the raw materials meet production requirements.

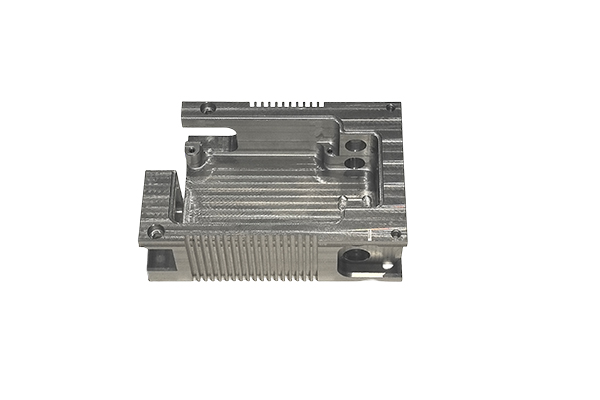

The mold is a key equipment in the processing of injection molded nut embedded parts. Its design rationality and manufacturing accuracy directly affect the quality and production efficiency of the product. The mold design needs to consider factors such as the shape, size, and wall thickness of the product to ensure that the melt can evenly fill the mold cavity during the injection molding process. High-precision processing equipment should be used in mold manufacturing to ensure that the mold size and shape meet the design requirements. In addition, the mold needs to be regularly maintained and maintained to avoid the impact of wear and deformation on product quality.

The injection molding process is the core link of copper nut injection nut embedded parts processing. During the injection molding process, parameters such as injection temperature, pressure, speed and cooling time must be strictly controlled to ensure that the melt can fully fill the mold cavity and form a good injection molded part. At the same time, attention should also be paid to the exhaust problem during the injection molding process to avoid defects such as bubbles and shrinkage marks. After the injection molding is completed, sufficient cooling and curing treatment should be carried out to ensure the dimensional stability and strength of the injection molded part.

The installation and positioning accuracy of the embedded parts are key factors affecting their performance. During the processing of embedded parts, high-precision installation equipment and tools should be used to ensure that the embedded parts can be accurately installed in the predetermined position. At the same time, attention should also be paid to the connection method and tightening force between the embedded parts and the surrounding structures to ensure that the embedded parts will not loosen or fall off during use.

The embedded parts of injection molding nuts may be affected by factors such as environmental corrosion and mechanical wear during use. Therefore, after the processing is completed, the embedded parts need to be surface treated, such as spraying anti-corrosion paint, electroplating, etc., to improve their corrosion resistance and wear resistance. In addition, the edges and sharp angles of the embedded parts need to be polished to avoid scratches or damage during use.

Finished product inspection and testing are important links to ensure the quality of copper nut injection nut embedded parts. After processing, the finished product needs to be inspected for appearance, measured for dimensions, tested for mechanical properties, etc. to ensure that the product meets the design requirements. At the same time, reliability tests such as vibration tests and impact tests are also required to evaluate the reliability and durability of embedded parts in actual use.

During the copper nut injection nut embedded parts processing process, a complete quality traceability system should be established to record key information such as raw material procurement, processing process, and finished product inspection, so that the cause can be quickly traced and measures can be taken when problems arise. In addition, it is necessary to regularly analyze and evaluate the quality of the production process, identify potential problems, and continuously improve the production process and quality control measures to ensure the stability and reliability of product quality.

The key points of quality control in copper nut injection nut embedded parts processing involve raw material selection and inspection, mold design and manufacturing, injection molding process control, embedded parts installation and positioning, surface treatment and protection, finished product inspection and testing, and quality traceability and continuous improvement. Only by strictly controlling these key points can we ensure that the quality and performance of the product meet the requirements.