Precision manufacturing technology of solenoid valve processing

Release Time : 2025-03-05

Precision manufacturing technology in solenoid valve processing is a key link to ensure the performance and quality of solenoid valves.

As a key component in the field of automation control, the performance and quality of solenoid valves directly affect the stability and reliability of the entire system. Precision manufacturing technology can ensure that the solenoid valves meet the requirements of high precision and high quality during the processing, thereby meeting the needs of various complex application scenarios. Through precision manufacturing technology, the precise processing and assembly of various components of the solenoid valve can be achieved, and the sealing, durability and response speed of the solenoid valve can be improved.

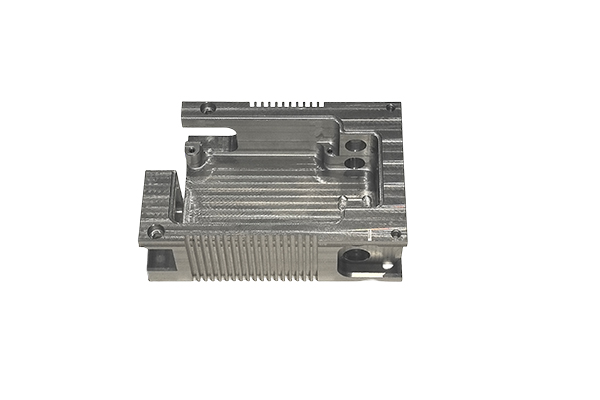

In solenoid valve processing, the application of precision processing equipment is crucial. These equipment include high-precision milling machines, lathes, grinders, boring machines, etc., which can achieve precision processing of key components such as solenoid valve bodies and valve cores. By adopting advanced CNC technology and automated control systems, these equipment can achieve precise control of the processing process and ensure processing accuracy and stability.

In order to ensure the processing quality of solenoid valves, precision measurement and detection technology is also indispensable. These technologies include high-precision measuring equipment such as three-coordinate measuring instruments, laser rangefinders, microscopes, and non-destructive testing technologies such as ultrasonic testing and magnetic particle testing. Through these technologies, the various components of the solenoid valve can be accurately measured for size, shape and defect detection to ensure that the processing quality meets the design requirements.

In solenoid valve processing, material selection and processing are also important components of precision manufacturing technology. The key components of the solenoid valve are usually made of high-strength, corrosion-resistant and high-temperature resistant materials, such as stainless steel, brass, etc. These materials need to undergo precise processing processes, such as heat treatment, surface treatment, etc., to improve their mechanical properties and corrosion resistance. At the same time, the materials need to be strictly screened and tested to ensure that their quality meets the processing requirements.

The assembly and debugging of the solenoid valve are also important links in precision manufacturing technology. During the assembly process, it is necessary to ensure the precise matching and positioning of each component and the correct installation of the seal. During the debugging process, the performance of the solenoid valve needs to be fully tested, including pressure testing, flow testing, response time testing, etc., to ensure that its performance meets the design requirements.

In order to ensure the processing quality of the solenoid valve, a complete quality control system needs to be established. This includes formulating strict processing technology specifications, establishing quality inspection standards and processes, and adopting advanced quality inspection equipment and methods. At the same time, it is also necessary to continuously improve the processing process, continuously optimize the processing technology and equipment, and improve production efficiency and processing quality.

With the continuous advancement of science and technology and the rapid development of the field of automated control, precision manufacturing technology in solenoid valve processing will also usher in new development opportunities. In the future, precision manufacturing technology will pay more attention to the development of intelligence, automation and efficiency, and achieve real-time monitoring and control of the processing process by introducing advanced sensors, actuators and control systems. At the same time, the research and application of new materials, new processes and new technologies will be strengthened to further improve the performance and quality of solenoid valves.

Precision manufacturing technology in solenoid valve processing is a key link to ensure the performance and quality of solenoid valves. By adopting advanced processing equipment, measurement and detection technology, material selection and processing technology, assembly and debugging technology, and quality control system, precise processing and high-quality production of solenoid valves can be achieved. In the future, with the continuous development of science and technology, precision manufacturing technology will play a more important role in solenoid valve processing.